Optical bonding

To inspire you as our partner we rely for optical bonding and for refining our touch screens, depending on the project, both on vacuum technology and wet bonding.

Here are sticked together both touch screens and glass plates with each other or with the display under clean-room conditions.

Vacuum bonding is qualified for all displays, currently up to the size 60'' and for touch screens of nearly all technologies. Wet bonding shows its potential especially in more little displays.

A fast sample production is possible.

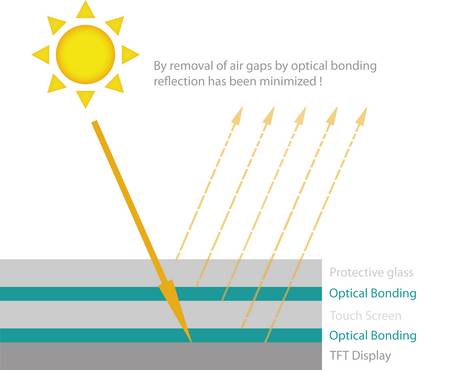

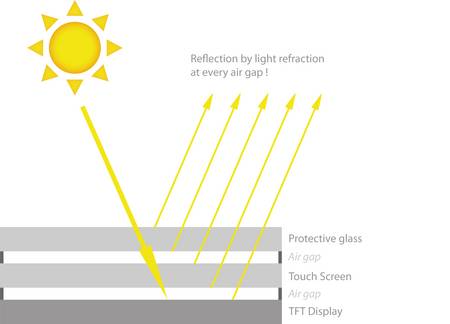

Advantages of Optical Bonding:

- less reflection - by sticking together the glass plates light refraction is reduced and the contrast increased. Therefore better readability without higher power consumption even in case of critical lighting conditions.

- no condensation - as there is no air gap between glass plate and touch screen or display, no moisture can penetrate and settle out, condensation is excluded.

- higher robustness - a bonded design is more stable and resistant against mechanical loads, thus the device becomes generally more robust, too.

- longer service life - by closing the isolating air gap between the glass plates heat can escape to the outside, a better heat dissipation is created.

- dust-free version - by clean-room production the inclusion of particles and thereby caused optical disturbances are prevented.

- improved design - improved appearance of the display.

We offer our Optical Bonding Service - independently or complementary to our standard versions - for every available display. Addionally we have also experience in procurement of displays.

Request us!